Zinc Coating Variants and Their Application Industries for Galvanized Steel Coil and PPGI Coil

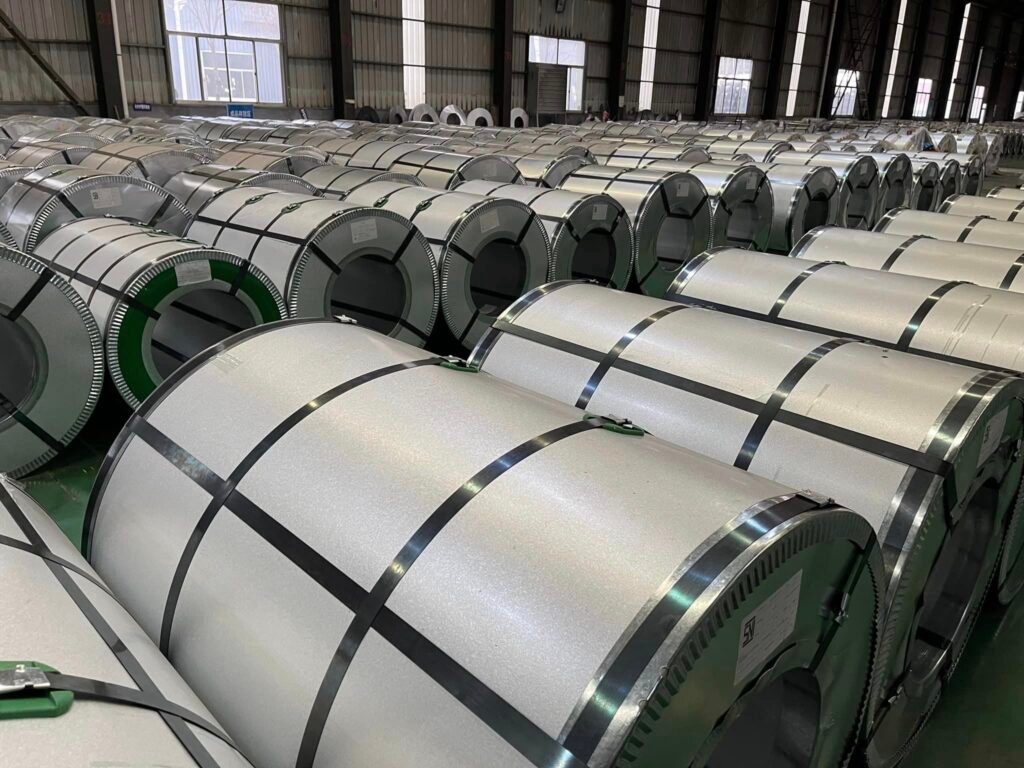

Galvanized steel coils and pre-painted galvanized iron (PPGI) coils offer exceptional corrosion resistance and durability, thanks to the zinc coating applied to their surfaces. The zinc coating variants, such as AZ20, AZ30, AZ40, AZ50, AZ100, AZ120, AZ150, AZ200, and AZ275, provide varying levels of protection and find diverse applications in different industries. In this post, we will explore the application industries for galvanized and PPGI coils with different zinc coating variants.

AZ20 and AZ30:

AZ20 and AZ30 zinc coating variants are commonly used for indoor applications, where moderate corrosion resistance is required. These coatings find application in industries such as interior construction, electrical enclosures, and appliances, providing a protective layer against moisture and minor environmental exposure.

AZ40 and AZ50:

With a slightly higher zinc coating, AZ40 and AZ50 find wider applications in both indoor and outdoor environments. They offer increased corrosion resistance and durability, making them suitable for applications such as roofing, ventilation systems, agricultural equipment, and automotive components.

AZ100, AZ120, and AZ150:

AZ100, AZ120, and AZ150 zinc coating variants provide enhanced corrosion protection, making them suitable for more demanding applications. Industries such as construction, infrastructure, automotive, and manufacturing utilize these coatings for roofing, wall cladding, structural components, industrial equipment, and electrical enclosures.

AZ200:

AZ200 zinc coating variant offers even higher corrosion resistance and is commonly used in applications that require long-term durability and protection against harsh environments. This coating finds application in industries such as marine, offshore structures, heavy machinery, and chemical processing equipment.

AZ275:

AZ275 is the highest zinc coating variant, providing the highest level of corrosion resistance and durability. It is utilized in demanding applications where extended protection is essential. Industries such as construction, infrastructure, industrial manufacturing, and transportation utilize AZ275 for applications that require resistance against corrosive elements, extreme weather conditions, and high mechanical stress.

Conclusion:

The zinc coating variants, including AZ20, AZ30, AZ40, AZ50, AZ100, AZ120, AZ150, AZ200, and AZ275, offer varying levels of corrosion resistance and durability for galvanized steel coils and PPGI coils. These coatings find applications in a wide range of industries, including construction, infrastructure, automotive, manufacturing, electrical, appliances, marine, and heavy machinery. By selecting the appropriate zinc coating variant based on the specific requirements of each industry, manufacturers and suppliers can ensure optimal protection and longevity for their galvanized and PPGI coil products.